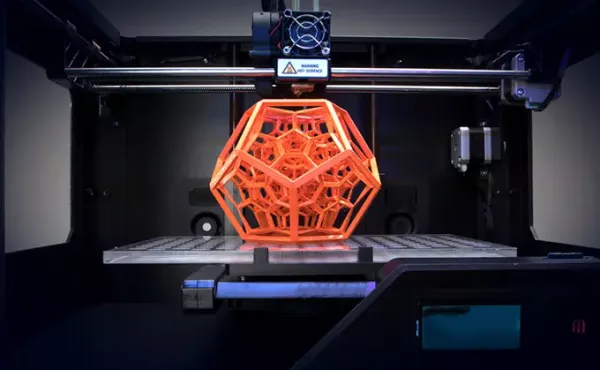

3D Printing Service

On-demand Plastic Printing

First Part provides industrial 3D Printing Services for the production of a wide scale of high-quality 3D printed parts. Our in-house capabilities include additive manufacturing techniques like SLA and SLS. With our online 3D printing services, First Part offers on-demand production services to make your plastic parts to completion and ready for shipping in as fast as 24 hours.

Our high level of repeatability makes our 3D printing service a great way to make one-off parts and low-volume prototypes that can be gradually scaled as demand increases. From instant quoting options to design for manufacturing reviews, material diversity, and complex designs, we encourage you to partner us in your product development journey and accelerate from design to production part in as quick as 1 day. To get started, simply upload your design and click here to receive a free quote!

What is 3D Printing

3D Printing refers to a transformative approach to manufacturing technology that creates lighter and stronger 3-dimensional objects layer by layer. 3D printing, also referred to as Additive Manufacturing (AM), constructs a part from a CAD model or digital file by bonding a layer unto a preceding layer of melted material till the final form of the part is attained.

3D printing can be used with a variety of materials including thermoplastics, ceramics, composites, edibles, glass, and even metal powder.

The structure of the part is contained in the computer-aided-design file (CAD) that creates .STL files that “slices” the part into thin layers and informs the print hear or nozzle on how, where, and how much material should be deposited layer by layer.

Our experience has allowed us to leverage our machine capabilities to deliver low-volume batch production of as little as 50 to 1000 units, while operations are very scalable to achieve up to 10,000 parts at an even lower cost-per-part. Post-production, all parts can be further processed with anodizing, drilling, tapping, or machining to protect, engrave, or improve your part’s ergonomics.

Choosing the Right 3D Printing Technology for Your Part

First Part’s 3D printing service is streamlined and efficient. This means that whatever your needs are, prototype, or high-quality production parts, you can choose from our processes to meet your project needs.

· Direct Metal Laser Sintering (DMLS)

DMLS machines are adept at producing parts with complex geometries and features that would otherwise require assembly when other techniques are used. DMLS uses a fibre laser to sinter atomic metal powder, welding the powder to each other till a full metal part is formed. The process is similar to SLS. This technique is great for making parts that place some emphasis on surface features and parts with high-resolution and detail.

· Direct Metal Laser Melting (DMLM)

Unlike the DMLS process, DMLM is a 3D printing technique where the metal material is melted into ultra-thin liquid pools. Through the use of a laser, heat is directed at the layers of metal powder to produce dense, non-porous parts with fine and homogenous properties.

· Fused Deposition Modelling (FDM)

FDM is an additive manufacturing technology widely favored for its speed, cost-efficiency, and precision. FDM machines heat and extrude plastic filaments layer by layer to make a part. FDM is a great option for making parts that require high strength and rigidity.

· Stereolithography (SLA)

SLA uses photo-polymerization to make plastic and ceramic parts. SLA machines direct an ultraviolet (UV) laser selectively at a photosensitive resin. The UV rays proceed to cure the resins and make solid end parts that are well suited for temperature extremes.

· Selective Laser Sintering (SLS)

Sintering allows for the creation of solid parts using heat to selectively melt, but not liquefy the material unto a print bed. The process continues layer by layer until the final part is formed.

SLS represents a more industrial approach to 3D printing, making high-quality plastic, metal and ceramic parts to certain strengths. The capability of the SLS printer varies with the power of the laser. SLS-printed parts will usually need to be oven-treated or kilned before they completely solidify and reach full strength.

SLA VS SLS

Choosing the right 3D printing technique isn’t a clear-cut process. This is because both SLS and SLA technologies have pros and cons. Often, there are trade-offs to be made before deciding on what method to use. Generally, the following factors are considered in selection:

· Part Strength

SLS parts are generally stronger and tougher than their SLA counterparts.

· Cost

SLS parts usually cost higher than similar 3D-printed SLA parts.

· Tolerances

SLA parts have tighter dimensional tolerances than SLS parts.

· Surface Finish

Parts made with 3D-printing SLA technique have better surface finish with higher level of details than SLS parts.

· Size and Geometry

SLS printing require no supports and have a larger build area, making them suitable for making larger parts with more complex geometries. SLA parts on the other hand are usually smaller, with less flexibility to create parts with complex geometries.

· Material Options

SLA resins are more expensive than SLS powders. Post-processing, SLA resins are toxic and more time-consuming to clean while SLS parts are easier to deal with.

· End Use

SLA parts are usually brittle and fragile, making them not very suitable for mechanical applications. SLS parts on the other hand are usually stronger and can satisfy a number of mechanical purposes.

What Are The Adventage Of 3D printing

Rapid Turnaround

With zero tooling cost and no intermediate processes, 3D printed parts can be made available in as quickly as 24 hours.

Durability

Using lattice and complex design features, 3D Printed parts can be made to be very durable, flexible, and resistant to environmental factors.

Cost-effectiveness

3D printed parts have lower cost-per-part as the process only uses the required material with no tooling costs for production. It is one of the most cost-effective operations for low-volume, one-off, or small batch production runs.

Material Divercity And Options

The diversity of 3D printing means that you can choose from numerous plastic and metal materials to manufacture your prototype and end parts, leveraging an array of material properties to get the best out of functionality, accuracy, and finish.

Complex Geometry And Features

3D printing can build parts with complex features and geometries that are otherwise impossible with other manufacturing processes at no additional cost.

Zero Waste

Unlike subtractive manufacturing where materials are shaved off a workpiece, 3D printing builds part from the ground up, using only what is required for each production run.

Precision Part

Achieve high accuracy and precision with the high standards of digital manufacturing. Additive Manufacturing also makes tolerances within the +/- (0.005 to 0.01) range possible depending on budget and mechanical specifications.

Effciency

3D printing does away with the bottlenecks that are common in other manufacturing processes. Once a CAD file is completed, the 3D printer can begin to create your part without any lengthy setup operations.

Adaptability

Since 3D printing requires no tooling, errors and design improvements can be made seamlessly by editing the digital CAD file. There is therefore lesser risk involved from the lack of tooling and faster corrections effected through digital design operations.

Applications Of 3D Printing

First Part 3D Printing and additive manufacturing techniques can be used for any of the following purposes:

High-precision End-part production

Leverage the high precision and consistency of additive manufacturing to make advanced 3D printed parts ready for end-use. Additive manufacturing is also ideal for the production of parts with bespoke features, complex geometries, lattices, and internal structures.

Biomedical Applications

Additive manufacturing and 3D printing can work with numerous biocompatible materials to make crucial orthopaedic components, prosthetics, surgical instruments, and dental apparatuses for medical applications.

Rapid Prototyping

3D printing can be used to accelerate product development cycles, moving from ideation to fully-functional prototypes and complete end-parts in as quick as 24hours.

Low-volume Manufacturing

3D printing is ideal for making small batches of prototypes or production parts without any tooling costs. With our online 3D printing services, businesses can make as little as 1 to as much as 100 units of high-resolution 3D printed parts at cost-efficient rates.

Material Options

Additive manufacturing is very versatile and can be used to produce durable and complex parts from synthetic plastics, thermoplastics, metals, and rubber-like plastics. Each material boasts of certain properties like mechanical performance, corrosion resistance, and high strength-to-weight ratio. See below the most common options for making 3D parts:

· Plastic

· Acrylonitrile butadiene styrene (ABS)

· Polylactic acid (PLA)

· Polycarbonate (PC)

· Nylon

· PPSF

· Metal

· Stainless Steel

· Aluminium

· Titanium

Finishing options

At First Part, our high-quality 3D printed parts may be put through any one or a combination of the following processes to deliver protection, improve surface texture, and enhance cosmetic appearance. Depending on the 3D printing process and material, any of these finishes may be applied to make your parts look and feel as intended:

· Standard/AS Manufactured

3D printed parts are sand-blasted to remove the remaining powder. The surface finish is similar to the granular/crystalline structure of a sugar cube.

· Media Tumbling

Media tumbling involves the use of a medium to de-powder the part after the standard routines. The parts have smoother edges and finesse.

· Bead Blasting

A surface smoothing operation that involves the direction of fine glass beads at a part’s surface under high pressure. Bead blasting creates a smooth, uniform surface finish on the part.

· Sanding

A surface smoothing and polishing method are done with the aid of sandpaper or sand. The size of the pores in the sandpaper determines the type of smoothness achievable.

· Clear Coating

Clear coating is a popular cosmetic procedure used to create a clear cosmetic appearance in 3D-printed parts.

· Painting

3D printed parts may be masked and spray-painted to any color with automotive quality paints after sanding and polishing have been carried out to smoothen the surface.

· Painting

Electroplating (such as Nickel plating) is used to improve the strength and durability of metallic parts.

· Polishing

Used for creating high-quality surface finish in 3D printed parts. Before polishing, parts should be sanded and smoothed to ensure that final surface looks and fees as intended.

· Texturing

Texturing helps to enhance ergonomics, cosmetics, and weather resistance. It is used to give 3D printed parts improved grip, reduce their slipperiness, and mimic certain textures.

· Custom

An array of custom finishes are also available for your part depending on the material and purpose of the end-use part.

Can’t find the desired finish? Click here to go to our finishing page and learn more about our array of finishing options in detail. We also offer custom finishing touches to help you achieve the desired finish or finishes for various parts.

Why Choose Us

With over ten years’ experience in Injection Molding, Insert molding, and Overmolding services, First Part is one of the best prototyping and Injection molding manufacturers in China. Here’s why:

Quality and Reliability

First Part is dedicated to meeting high quality standards, delivering part on time with precision, accuracy and reliability. We follow strict quality control systems to ensure that only the best parts are delivered.

Instant Quoting And DFM

Instant quoting and free design for 3D printing analysis to help optimize your design, suggest improvements, and receive an accurate quote in as fast as 24 hours.

Cost-effectiveness and Turnaround

Our services ensure cost-effectiveness and quick turnarounds for low-volume and mass manufacturing. Through budget and design optimization, First Part can make your past at competitive market rates.

Capacity and Network

Excellent in-house capacity and capabilities, guaranteeing that your parts are made from top quality from start to finish. Enjoy non-disclosure agreements and take advantage of our network of over 20 CNC machining centres to manufacture parts home and abroad.

FAQs – 3D Printing

· What technologies are available for 3D printing?

As at now, we have industrial Selective laser sintering (SLS) and Stereolithography (SLA) technologies for 3D printing on low-volume and rapid prototyping capacities.

· What materials can I 3D print?

Metals, ceramics, engineering-grade thermoplastics and silicone materials can all be 3D printed.

· How do I get a quote for 3D printing?

We make it easy for you to jump start your production. By simply clicking here, you can can receive a free quote and design-for-manufacturability analysis in a couple of hours.

· Why choose 3D printing?

3D printing is quick, affordable and easy to modify. Because there is no hard tooling, changes can be quickly made from the CAD data file and sent to our industrial printers. 3D printing also has near-zero waste, versatility and an significant ability to achieve complex geometries and intricate shapes.

Request A Quote

Ready to get started? Contact us with details of your project to take advantage of our automated electronic quoting service, design verification process and excellent customer feedback program. With an extensive amount of finishing options to compliment a wide range of material types, over 100 CNC machining centres and deeply-rooted industry experience, Firstpart is always willing to collaborate and deliver functional end-use parts with quality you can trust every time.

Click here to get in touch with us and get a free quote now!