Plastic Injection Molding Service

- 100+ Materials & Finishing For Choosen

- 1-10,000 Flexible MOQ

- T1 Sample As Quick As 7 Days

- Prototyping & Production Mold-making

Certifications: IATF 16949:2016, ISO 9001:2015

First Part specializes in the use of rapid prototyping and On-demand manufacturing techniques to produce high-end plastic injection molded parts and mold tools. Our plastic injection molding process is capable of making custom prototypes and end-use parts in as quick as 7 days. At First Part, cost-efficiency is optimized by using aluminum mold tooling that can reproduce thousands of parts and accelerate your product development cycle.

We stock over 100 plastic resin materials to choose from and complement molded part with an array of finishes. To get started, Click here to upload your project design information and receive an instant quote.

Advantages of Injection Molding Service - First Part

10+ Years Industry Experience

Expertise, high quality manufacturing;

Industry application: automotive, medical, electronic, digital consumer etc.

Custom Design Capability

Offering free design service.

Quick DFM, complex mold design available.

Cost-effectiveness

Affordable prototyping & production tooling;

Free mold maintenance;

Re-order discount.

Efficiency & Quality

T1 sample within 7 days;

Strict QC policy;

Quality steel tooling

Flexible Materials & Finishes

Over 100 materials + custom materials for choosen;

Multi finishes to your needs.

Responsive Customer Service

7*24 customer service;

Quick reply within 24hrs

Easy Steps For Working With Firstpart

1. Upload Your Design

Upload your 3D design file with online form

2. Get Instant Quote & Free DFM

Quick quote and expert DFM as fast as 1 day

3. T1-V1 Mold Design & Making

Customize, design and making your mold. Make sure you get the satisfies mold.

4. Production & Shipping

Manufacturing your products and shipping to your place. Affordable price guaranteed.

Our Injection Molding Capabilities

In First Part, experienced team for plastic injection molding service. Our injection molding and rapid processing services perfectly match. We can efficiently and accurately complete custom parts.At the same time, our injection molding services can suit the application requirements of any industry.

Mold Making

Our competence and capabilities are centered around integrating digital manufacturing technologies with conventional manufacturing processes. This is why we can use high-quality 3D designs to rapidly manufacture high-precision mold tools in a matter of days.

We offer rapid tooling, mold making, and die manufacturing for both low-volume production, mass production, and prototyping. Our expertise includes steel, and aluminum tooling, and mold maintenance, redesign services.

Plastic Injection Molding

First Part uses high-quality thermoplastic materials to deliver top-grade plastic injection molded parts in as quick as 7 days. From our instant quoting service to design evaluation, toolmaking, die, and mold production, and finally injection molding, we stay true to our promise of quality.

Our entire injection molding capabilities include insert molding, mold making, rapid tooling, and overmolding.

Overmolding

Overmolding is an injection molding operation that is used to make a single part from multiple materials. At First Part, we can mold a thermoplastic material into a second material to leverage certain performance and characteristic attributes of the materials to complement functionality. An example is the solid plastic body and rubberized handles of toothbrushes. Overmolding is very effective for creating composite parts, costing lesser than other production techniques that require assembly of separate components.

Insert Molding

Insert molding is one of First Part’s injection molding capabilities, enabling us to create or integrate plastic fragments and components (inserts) to the pre-fabricated metal part. Through our expertise in cross-technology fabrication, we can use sheet metal and CNC machining to make units of your metal part and employ insert molding to introduce plastic parts. Insert molding can be used in making tools that are sharp and require a grip. Examples include scalpels, fasteners, bushings, or clips.

FirstPart Injection Molding Solution

Prototyping VS Production Tooling

We can do both types, you can choose according to your need.

Prototyping

- Low MOQ from 1

- Cost-effective

- Steel tool

- Low-volume manufacturing

Production

- Higer quality tooling

- Million molding shot

- Lower parts pricing

Trusted Supplier

Injection Molding Your Parts

1. Plastic injection molding, insert molding, overmolding, etc.

2. 100+ materials chosen including custom materials

3. Quick lead time & affordable price & FREE DFM

Finishing options

Molded parts can be finished in many ways that may cover purely aesthetic finishes or offer some form of protection to the part. Finishes should beautify and enhance the sophistication and functionality of any part. At First Part, our Injection-molded parts may be finished in any of the following options:

- As manufactured

- Bead blasting

- Pad printing

- Etching

- Textured finish

- Laser finishing

- Semi-Glossy

- Glossy

- Matte

Material Options

Plastic, Elastomers and Synthetic Rubber

· Polyphenylene sulfide (PPS)

· Polypropylene (PP)

· Acetal polyoxymethylene (POM)

· Acrylonitrile butadiene styrene (ABS)

· Glass-filled polycarbonate (PC-GF)

· High-density polyethylene (HDPE)

· Low-density polyethylene (LDPE)

· Polybutylene terephthalate (PBT)

· Thermoplastic vulcanizates (TPV)

· Polycarbonate (PC)

· Polyolefin Elastomer (POE)

· Polymethyl methacrylate (acrylic) (PMMA)

· Nylon 66 (PA66)

· Glass-filled, polyamide (PA-GF)

· Polystyrene + polyphenyl ethers (PS-PPE)

· Thermoplastic elastomer (TPE)

· Thermoplastic polyurethane (TPU)

· Custom-sourced Resins

· Customer-supplied materials

The above materials are the most common stock material options. If your desired material is not listed above, please contact our team here. You may learn more about our other options and custom material applications by clicking here to go to our materials page.

Injection Molding Applications

First Part Injection Molding Operations can be applied in:

· High-functional end-part production

Injection molding is widely used in making functional end-use parts that will replace metal parts in most components. Choose from materials to finishes to make high-quality parts that are of high strength and less weight than metal counterparts.

· Rapid tooling/Mold making

We can use our optimized injection molding process to manufacture molds, tooling (cores and cavities), and dies for use in making any range of budget, volume, and production times.

· Rapid Prototyping

Take advantage of low-cost tooling options to allow you to make highly-functional parts that are suitable for functionality testing. Even when tooling with aluminum molds, our injection molded parts are almost certain to outperform 3D printed or CNC machined parts from the same material. A low-cost mold can be made in a shorter window, and depending on size and geometry, it could be used in making many volumes. (up to thousands of prototypes)

What Is Plactic Injection Molding?

Plastic injection molding is the most widely-used manufacturing technique for the production of mass units of plastic parts that serve industrial and commercial purposes. Plastic injection molding also has the highest range of materials, color, and configuration when put side-by-side with processes like CNC machining or Additive manufacturing.

The process essentially involves the injection of molten plastic material (resin) under high pressure into the cavity of a metal die before cooling the mold to solidify the shape into its final part. Depending on the part size, material, and design complexity, the injection molding cycle may span anywhere from a few seconds to a couple of minutes.

In First Part China Limited, we can handle the plastic injection molding rapid tooling for both high-volume and low-quantity parts production. Using the technical maturity to produce high quality custom plastic molded parts for defense, automotive, medical, aerospace and consumer products.

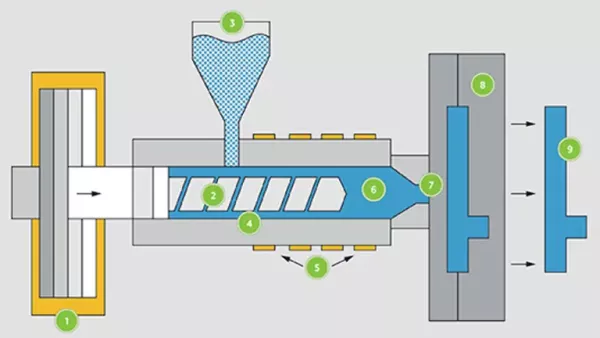

Our Plastic Injection Molding Process

At First Part, we design our plastic injection molded parts in 6 quality-driven steps:

1.Material preparation

Dry plastic pellets may be used as they come or blended with colorants or fillers.

2.Loading

The pellets are loaded into the hopper of the molding machine and transported by a screw in the barrel towards the mold.

3.Heating

The dry pellets are then heated inside the barrel of the machine until they form the liquid resin, in a fully molten state. The mold is also heated.

4.Injection

The molten resin is injected under high pressure into the heated mold cavity through a gate. The resin fills the cavity and takes the form of the mold tool.

5.Ejection

The cooled and now-solid part is ejected into the loading bin by opening the mold. Ejector pins aid the removal of the part from the mold. A new injection molding cycle may now commence.

6.Cooling

The mold is cooled to solidify the part within.

Injection Molding Service - What you can get?

Quality and Detail

The high pressure involved in Injection molding means that the molten material penetrates the nook and cranny of the mold before solidification and curing. This allows engineers to design complex parts, inscriptions, details, and elements into their part with the assurance that every part will be made just as they imagined.

Scalability and repeatability

Injection molding can produce thousands to millions of parts that are exact and identical to the master mold tooling.

Cost-effectiveness

An Injection molding tool made from steel can make hundreds of thousands of parts, spreading the tooling cost over a large volume and ultimately lowering the cost-per-part.

Material diversity and options

Injection molding is the most diverse manufacturing technique when it comes to material selection and considerations. Injection-molded parts can be made even stronger by using fillers and composite materials into the liquid resin to improve its tensile strength.

Low-volume manufacturing

Aluminum tooling lower setup and tooling costs, ensuring that injection molding can be used for rapid prototyping and low-volume manufacturing.

Custom Surface Finishes

With the proper process optimization techniques, injection molded parts can be ejected ready-to-use or finished in an array of popular or custom methods to ensure that your part look and feel as intended.

FAQs – Plastic Injection Molding

What Injection molding capabilities does First Part have?

First Part’s Injection molding capabilities are reliable, precise, and scalable. Our robust manufacturing hubs make us one of the most trusted outlets for general metal and plastic fabrication. Here’s a summary of all our injection molding capabilities.

What are the advantages of Plastic Injection Molding?

Plastic injection molding is one of the cost-efficient methods of making thousands of finished parts quick and accurate. One tooling has been completed, the other parts can be fabricated in large volumes that any other manufacturing technique.

How long does mold tooling take?

Depending on the volume of parts, the need for heat treatment, design, and geometric complexities, a standard plastic injection molding tool can take anywhere between 7 – 10 days to manufacture.

Request A Quote

Ready to get started? Contact us with details of your project to take advantage of our automated electronic quoting service, design verification process and excellent customer feedback program. With an extensive amount of finishing options to compliment a wide range of material types, over 100 CNC machining centres and deeply-rooted industry experience, Firstpart is always willing to collaborate and deliver functional end-use parts with quality you can trust every time.